Add to Cart

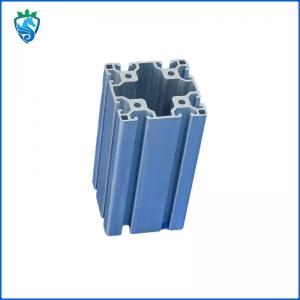

4040 Plate Chain Assembly Line Aluminum Alloy Profile Industrial Aluminum Profile

The aluminum profiles on the assembly line can customize different structural frames according to the customer's size and model, and use auxiliary materials to connect frames with different appearances. For example, a dust cover for equipment is a cover that protects automation equipment. This cover is usually custom made for the device. Products that are well insulated from the outside world are usually supported by metal. In the past, the dust cover was made of iron or steel, which required welding, was heavy and inconvenient to disassemble. Today, industrial aluminum profiles are mostly used for replacement. Industrial aluminum profiles are light and convenient, dust-proof and rust-proof, easy to assemble, easy to disassemble, environmentally friendly and hygienic, and require no maintenance.

Name | Assembly Line27 |

Material | Aluminium alloy |

Surface Treatment | Electroplating, spraying, wire drawing, anode, as customer's requestment |

Colour | Stainless steel, bronze, gold, black or as customer's requestment |

Temper | T3-T8 |

Shape | Square, Flat, Round, Hollow, Oval, Triangle, U-profiles, L- profiles,T-profiles, H- profiles,or as customer's requestment |

Certification | ISO9001,ISO14001,ISO45001,IATF 16949:2016 |

Product Display

Application

1. Car simulator bracket

2. Workshop safety fence, large-scale equipment protective cover, light screen and anti-arc screen

3. Large maintenance platform, climbing ladder

4. Medical device bracket

5. Aluminum profile photovoltaic support

6. Various shelves, storage racks, large-scale cultivation room material racks, aluminum profile racks

Certificates and Honors

Factory display

Company Profile

Jiangyin Longkang Metal Products Co., Ltd. is located in Zhouzhuang Town, Jiangyin City - the largest aluminum extrusion profile production base. Covering an area of more than 35,000 square meters with more than 350 employees. We focus on metal customization, special-shaped aluminum profiles, aluminum profiles, aluminum tubes, rail transit series, doors and windows aluminum profiles, heat sinks, CNC processed aluminum profiles, interior decoration series, bending series, etc. We also have precision anodizing and various surface treatments, such as PVC film, wood grain, electrophoresis, powder coating, anodizing, etc. After more than 20 years of development, The company has become a modern aluminum production enterprise with perfect quality management system.

The company implements "three guarantees" for the sales of "Keyan" aluminum profile products, that is: if the user finds that there is a quality problem or the goods are not returned or replaced, the loss caused by the package will be compensated, and the after-sales service package will be satisfied. In order to do a good job of "Three Guarantees" and after-sales service, the company attaches great importance to starting from the source. First of all, the whole company strictly implements the ISO9001-2008 quality management system, cites advanced ERP management software, and establishes a perfect product quality tracking system. Any problems in any link can be traced back to the root cause in time. It can solve the hidden quality problems at the fastest speed. The feedback work procedure of product quality information is gradually improved and standardized, and all kinds of quality information can be timely fed back to relevant departments and solved. In terms of production management, a set of specific management measures has been adopted to prohibit defective products from flowing into the next process and refuse substandard products to flow out of the workshop. Operators, teams, squad leaders, and quality inspections strictly control each layer to ensure that 100% of the products in the warehouse are excellent or qualified. At the same time, the products stored in the warehouse should be neatly stacked, with obvious spacing and identification. The warehouse controls the delivery, checking, and weighing according to the number of the bill of lading, and provides the user with the exact products required by the user. Due to the strict control of the service process, there has been no return or economic loss caused by the company's wrong delivery or incorrect goods. In the after-sales service of the product, the company also provides technical support for new users' technical problems, and can also provide door-to-door service according to the needs of users, so that new and old users can master the product application method as soon as possible, so that users can appreciate the excellent after-sales service of our company's products. Impressed by the service! It will leave a deep impression on "Keyan" for new users who purchase Keyan's aluminum alloy products.

FAQ

Q: What is the thickness of the anodizing? Can you do 12um?

A: Our normal thickness is about 10 um. Yes, we can do 15 microns and above.

Q: What colors can powder coatings be used for? The thickness of the powder coat?

A: We can do any color for powder coating as long as you can provide color samples. Our usual powder coating thickness is 60-80um.

Q: What color can the wood grain be?

A: Our most popular colors are Western Red Cedar, Australian Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other color, we can provide the color according to you.